Introduction

The creation of hair clippers can be traced back to the late 19th century. They were first created by a Serbian pig breeder known as Nikola Bizumic. He had created the first hair clipper, but it was all manual. With this, barbers were able to cut hair short in an even shorter amount of time. Later, this technology was adopted by a man named Leo J. Wahl in the early 20th century. He added in a vibrating electric motor which would make the blades oscillate from side to side, just like the ones that are used today. However, with this technology, he initially invented a head massager for his uncle, J. Frank Wahl, who opened a manufacturing plant to help Leo sell the head massager. Leo later had to take control of the manufacturing business when his uncle was drafted to the Mexican Revolution. Because of this, Leo applied for patents on his electromagnetic hair clipper and had them mass-produced at Wahl Manufacturing Company. At this point, he had created clippers with a motor in the hand, instead of being connected to a separate external one This would lead him to patent a few other designs of hair clippers, buy all the stock of the company, and change the business name to the Wahl Clipper Corporation. As time went on, he would meet with barbers to help improve the technology until his death in 1957.

There are a few different variations when it comes to the electric hair clipper today. But its main three parts are all relatively the same. They all have a motor, and a piston is also connected to that motor. This piston holds a set of small sharp blades. When an electric current is added, the motor starts to move quickly in a horizontal motion. This causes the blades to rub against each other, allowing hair to be cut. Many blades are stainless steel, so they’re rust-resistant. However, ceramic ones can also be used and they have their own set of advantages and disadvantages. The blades in general do not require a whole lot of maintenance either. Finally, guards allow the blades to be covered to a certain extent, and provide an optimal cutting length.

However, the technology being presented will feed off of these ideas and make the process of cutting hair a lot smoother. It would appeal to those who don’t want or have the time to go to a barber and get a haircut. After the initial payment for the clipper, they can get free haircuts anytime they want. This is especially beneficial in the climate that everyone is living in now, with the question of whether barbershops and salons will remain open.

Current Technology v. Auto-Trimmer

Currently, there are many types of hair clippers, but they require you to change the guards manually to be able to affect how much hair is cut. And to use these clippers, you’d have to have some experience or idea of how you’re going to cut your hair. For someone who wants to cut their own hair, but doesn’t know-how, the trimmers that are used today just aren’t ideal. With the technology of the auto trimmer, its small and cordless design can do all of that for you without the hassle. The idea is to use two small, adhesive patches. One on the forehead, and the other at the back of the neck. With AR mapping, the head of the individual can be scanned so that the trimmer can determine where the size of the guards would change in regards to the head and haircut.

Technical Description

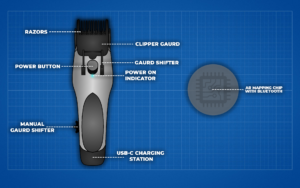

The Auto-Trimmer hair clipper is made up of seven main components, the razors, the clipper guard, the guard shifter, the power button, the manual guard shifter, the USB-C charging station, and the AR mapping sticker that comes with Bluetooth. The Auto-Trimmer works like any other hair clipper, but its innovation is the fact that it can fade automatically without having to change between different guards. The plus side to this is that you can have little to no skill in cutting hair and you will still be able to give yourself a fade as you would get at the barber shop. The way it works is as follows: the AR mapping stickers are placed around your hairline so that the clipper will essentially know how your head is shaped and it will know how fast to shift the guard. For example, if you have a big head the guard shifter would move the guard at a slower pace so that the transition of the fade suits your head shape and vice versa. The clipper knows where it is because the AR mapping stickers maps the shape of your head and sends it to the clipper via Bluetooth. The stickers really allow you to have that perfect barber finish so that each customer gets a fade that is most suitable for their head shape, if we had a one-size fits all type of automatic fade clipper some people would look a little weird because the fade would not fit their head shape. Additionally, the Auto-Trimmer comes with a manual guard shifter located at the bottom of the clipper which is a gear that you can rotate which controls the guard shifter to move up and down thus moving the guard so that you can personally control the guard if you wanted to. Finally, the clipper is powered with a USB-C cable so that the clipper can be wireless; a wireless clipper is much better as opposed to wired because it gives.

Figure 1: Model of Auto-Trimmers and AR Mapping Chip

How To Use It

It’s very simple to use. First you’d apply the AR mapping stickers to certain points on your head. You use your phone to “scan” your head. This is done by taking the phone, with the app already booted up, and moving the phone around your head. This will create a layout of your head shape. After this is done, you pick certain characteristics that you want for your haircut. The overall look, type of fade, etc. Then, just carefully move the clippers around your head and let the Auto-Trimmer do the rest.

Process for the Innovation

In the current dynamic and turbulent times, inventing is easier than ever. Coronavirus has introduced a whole new plethora of problems just waiting to be solved. So, while contemplating the new problems the world faces, one stood out of the rest. Due to social-distancing and quarantine restrictions, visiting the barber became difficult and dangerous. There was a large need for a product that can replace the service usually done by trained barbers. While hair trimmers already exist, our company saw how hard it truly was to cut your own hair well. We then came up with the idea for our product, auto-trimmers, hair trimmers that automatically adjust their guard to give their user the freshest cut available. However, we first would have to find the technology that enabled the guard to know when to retract and extend. We found a solution in Google’s ARCore, an augmented reality developer platform. Using ARCore and two tiny Bluetooth stickers attached to the middle of the user’s forehead and the base of their head, the user’s head is able to be mapped into AR. The trimmers then use the mapped head diagram to detect where on the head it is trimming and adjust the guard to the proper setting for the selected haircut. This will enable untrained customers to give themselves both a beautiful trim and clean fade, without the danger of catching Coronavirus.

From the conception of the invention to the first day it hits the shelves will take 9 months. Two months will be spent creating advertisements, finding and securing contracts to sell our trimmer in global store chains (i.e. Walmart, Costco, Target, etc.), and refining the Auto-trimmer design. After that, 6 months will be taken up with hiring and training the workforce and acquiring all the materials and equipment needed for production. One final month will be spent refining the production method and ironing out any defects in the final product. Then, Auto-trimmers will be sent all over the world. However, now onto explaining the entire business plan in detail.

The first thing that must be done is the design. As seen in the technical description, a model of the auto-trimmer was created. Using this model and research into the production of hair trimmers, our company has concluded that each auto trimmers’ material cost would be $71.48 (see Chart 1 for a breakdown of price). However, weighing in expenses for both labor and advertising, the retail price will be set to $348 per unit.

Second, workers must be hired to help the Auto-trimmers become a reality. A five-person advertising and marketing team will be hired to promote the auto-trimmers on all popular social media platforms. Each worker on the team will be paid $22 per hour, totaling $17,600 per month. Following that, a one thousand square foot factory will be acquired for production in Oklahoma City for $445,000. Fifty-six workers will be hired for the factory, composed of twenty-five assembly-line workers and three supervisors. The assembly-line workers will be paid $16 per hour and the supervisors will be paid $22 per hour, totaling $72,040 per month. Altogether, the cost of labor is $89,640 per month.

Finally, the renting price of the equipment needed to produce every part of the trimmers on the assembly line amounts to $360,000 per year. The daily production goal will be 5,000 auto-trimmers a day, placing the average production cost of the Auto-trimmers at $71.93.

| Materials | Amount | Description | Cost (per ounce) |

| Aluminum | 10 oz per unit | Forming the body of the clipper, the guard mechanism | $0.12 |

| Stainless Steel | 3 oz per unit | Forming the majority of the blades and accents along the clipper’s body | $0.06 |

| Titanium | 1 oz per unit | Plated on the clipper’s blades | $1.88 |

| Plastic (HDPE maybe) | 10 oz per unit | Internal carcass for motor, adjustable guard | $0.03 |

| Lithium Battery (3 hour charge) | 1 per unit | Rechargeable battery for cordless operation | $24.90 |

| Copper | 5 oz per unit | Internals controls of clipper, charging cord | $0.20 |

| Brass | 1 oz per unit | Plugs for charging cord and female port in clipper | $0.10 |

Chart 1: Materials Used to Create the Auto-Trimmer

| Type of Worker | Quantity of Worker | Hourly Pay | Monthly Pay | Total Pay (per month) |

| Advertising and Marketing | 5 | $22 | $3,520 | $17,600 |

| Assembly-Line | 25 | $16 | $2,600 | $65,000 |

| Supervisor for Assembly | 3 | $22 | $3,520 | $7,040 |

| Total Number of Workers | 33 workers | Total Cost of Workers | $89,640 |

Chart 2: Labor Wages and Quantities

Conclusion

Overall, the Auto-Trimmer can be considered a technological marvel when it comes to cutting hair. It will only elevate hairstyles from here on out. Its simplistic design is a result of years of research that has been done on this technology. However, the process of innovating it is no small feat and requires a large amount of work and resources to bring people a small but powerful tool in the palm of people’s hands.

By Adrian Damian, Eric Lange, and Santiago Lopez

References:

Dunn, K., & On. (2018, February 21). The History of Electric Hair Clippers. Retrieved November 18, 2020, from https://otcbeautymagazine.com/electric-hair-clippers/

Pandothebarber. (2020, April 10). How do Hair Clippers Work? Retrieved November 18, 2020, from https://professionalbarberclippers.com/informational/how-do-hair-clippers-work/